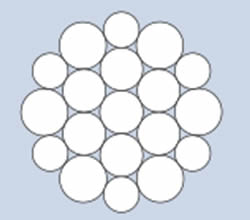

Cross laid wire rope

means each wire of different layers contacts in points and has relatively large spaces between wires. It is extremely flexible and generally used in slings. Compared with parallel laid wire rope, this one has smaller contact area which makes it easier to fail due to fatigue and shear over time.

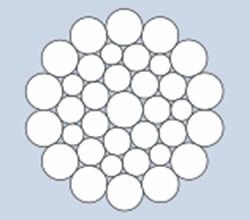

Parallel laid wire rope

has wider contact areas with minimal breaks caused by inside abrasion. They boast low bending fatigue and higher breaking load without any destruction of strand shapes taking advantages of their tight structure. Normally, parallel laid wire ropes can be classified into four types: seale type (S), filler wire type (F), warrington type (W) and warrington & seale type (WS) as shown below:

Bright, Galvanized or Stainless steel?

- Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

- Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

- Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

How Can I Find the Optimal Steel Wire Rope?

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

FC, WSC or IWRC?

FC – FIBER CORE

FC stands for fiber core, made of natural or synthetic fiber, which can provide excellent flexibility and resistance to contact pressure. The fiber core can store lubrication to reduce the friction between wire strands effectively. Meanwhile, the fiber core makes the rope lower deformable with low elastic rope elongation.

WSC – WARRINGTON SEALE CORE

WSC is abbreviation of wire strand core. WSC ropes features better heat resistance than FC ropes, meanwhile, increase metallic section provide added 15% of strength. However, WSC steel ropes are less flexible than those with fiber cores.

IWRC – IRON WIRE ROPE CORE

IWRC is short for independent wire rope core, which strengths the rope, reduce tensile stress in individual wires as well as makes the ropes more resistant to crushing. At the same time, IWRC wire ropes have the maximum heat resistance than others FC or WSC ropes.

There are many reasons to prefer us..!

Quality commitment

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Service commitment

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

Price commitment

As one of the largest manufacturers in Turkey, we can purchase better materials at a lower price. Then we transmit this saving to our customers by providing the most competitive price.

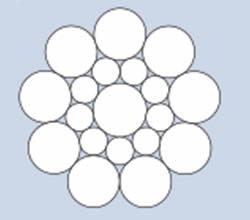

SEAL TYPE

The outer stands have larger diameter than inner strands for excellent abrasion resistance and high flexibility.

FILLER WIRE TYPE

With small wires in the valley between outer and inner strands, filler wire rope features good abrasion and excellent fatigue resistance.

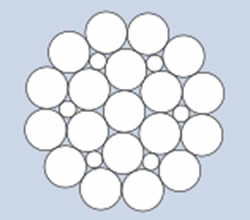

WARRINGTON TYPE

Warrington ropes feature alternative large and small outer strands for great flexibility with resistance to abrasion.

WARRINGTON SEALE TYPE

It is a combination of warrington type and seale type with large diameter and high abrasion resistance.

sddsd